In the arctic, life is dictated by the turning of seasons. And as our short-lived fall in Alaska begins its transition into the long, cold winter, the window you have for winter preparation is also beginning to come to a close. Pretty soon, ice will adorn every part of life, and the cold will make servicing your equipment a task that you may not want to complete until the spring thaw.

When the snowflakes begin falling, this is your cue that equipment servicing time is upon you. And being proactive has its benefits. After all, when your machinery is running in tip-top condition, this will save you time and money when the weather finally turns warm again.

Fall is the best time to service your equipment, get repairs done, and ensure that you and your crew are ready to go out on the next job.

Need service and maintenance help for your equipment before the winter sets in? Contact the experts at ESI Alaska today.

Why Should You Service Your Equipment?

The bottom line is, you’re not going to be working out in Alaska with faulty equipment. This can not only cause production delays and safety hazards but it can also cost you money in the long run. And nobody on your crew is going to want to be working with subpar machinery.

Equipment servicing, repair, and general upkeep are part of owning equipment, and a huge part of running a successful and productive business. And without the tools you need for the job, you’re likely going to be missing out on a top-dollar contract.

Out in Alaska, tough jobs require tough machines that run at an optimal performance level. And if you’re not servicing your equipment, you may find yourself without the tools or the means to get any work done after the spring thaw.

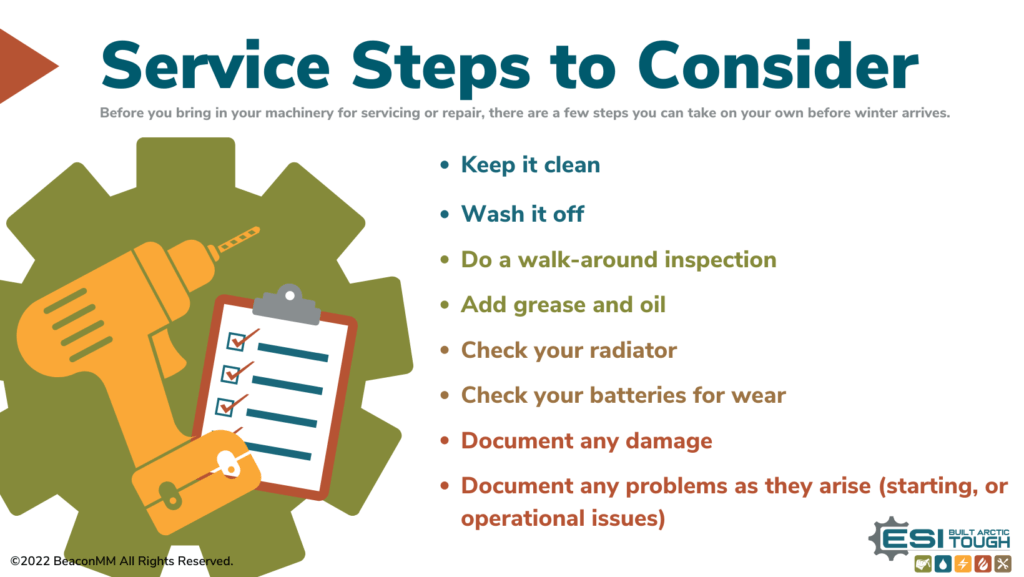

Service Steps to Consider

Before you bring in your machinery for servicing or repair, there are a few steps you can take to keep your equipment in shape before the winter sets in. And the following steps will also help to mitigate any service issues before they arise.

- Keep it clean

- Wash it off

- Do a walk-around inspection

- Add grease and oil

- Check your radiator

- Check your batteries for wear

- Document any damage

- Document any problems as they arise (starting, or operational issues)

- Make a parts list

Keeping up with your machinery can make all the difference in the world between a small servicing job, or a complete replacement which (depending on the equipment) may cost you thousands of dollars.

In addition, always check your equipment manuals for proper maintenance and upkeep tips. And when you perform maintenance routinely, you’re likely to see much less need for servicing and repair in the fall.

Dealing With Common Problems

If you’re out on the job and you notice your equipment begin to run poorly or inefficiently, this is a definite reason to pause. And your equipment might not be able to talk, but it can give you signs or signals that something is wrong.

No matter what type of machinery you’re using, whether it’s a generator or a wheel loader, the following short list covers the most common equipment problems that you may have to contend with.

Electrical Issues

Some of the most common problems come from onboard electronics that can incur damage. After all, wires and connection points are quite sensitive, and even a coating of dust can cause electrical problems to arise.

Cold climates also affect electronics and batteries significantly. In fact, an old battery may not last through cold weather. And this is why you need to ensure your electronic systems have been protected and any issues have been fixed.

Leaks

If you’re looking for a sign that something isn’t running properly, a leak is a good indicator. And whenever you notice any water, oil, or fluid oozing out of your equipment, this is your cue to take it in for servicing or make repairs on the fly. Because once you spot a leak, you may not have much time before your equipment breaks down.

For example, oil leaks can indicate you have broken seals or other issues that may require significant repairs. And any fluid leak could indicate the same problems. So, the last thing you’ll want to do is wipe the leak down and pretend you didn’t see it.

As a rule of thumb, if you see a leak, bring it in for repair. Don’t wait for it to break down on you when you’re out on a job.

Dirt & Grease

If you’re working around a lot of dirt, this is going to be a factor in how your machine operates. Though we love dirt, it can really gum up a machine no matter how it settles in. And the simple remedy for this is to keep your equipment clean at the end of a workday.

By simply washing off your machine and wiping down your equipment, you can save a lot of time, frustration, and money during the warm months.

How ESI Alaska Can Help

Here at ESI Alaska, no matter what issues have arisen with your equipment, we’re here to offer you the best service and support possible to keep you out on the job and in business.

With our top-quality team of engineers and fabricators on hand, our experts can assist you with all products we manufacture or rent. And no matter what the issue is, we’re confident that we can provide you with the best solutions for repairs, servicing, and support to keep your equipment running in tip-top condition.

Check out a few of the following services ESI Alaska provides:

- Kubota tractor servicing

- Parts for engines, burners, and ducting products

- Reconditioning services for old heaters

- Tioga reconditioning services

In addition to basic servicing needs, we also carry items from the following suppliers to assist you with any part replacement or service requirement to keep you working in Alaska:

- Blackmer

- Buyers Products Company

- Carlin Combustion Technology, Inc.

- Concut Diamond Products

- Engineered Performance Ducting

- Flagro

- FPT Powertrain Technologies

- Kaeser Compressors

- Kubota

- Land Pride

Keeping you out on the job is our job. And we pride ourselves in making sure you have the tools you need to work on those tough Alaska jobs. And with our service department at the ready, you won’t need to worry about your equipment during the long winter.

Preparing for the Winter

Sometimes storing your equipment is one of the best options. And the equipment you’ll need for the warmer weather may need a rest during the cold Alaskan winter.

If this is the case, bringing your equipment in for servicing during the fall is the best way to ensure that it’ll be ready to go once the weather gets warmer again, and you’ll be ready to get back out there and get to work.

Don’t let a simple task like equipment maintenance ruin your machinery. It’s one of the easiest things to skip over. But skipping over essential tasks for equipment upkeep is sure to cost you more in the long run.

Ready to get your equipment services before the winter sets in? Contact the experts at ESI Alaska today for support.